UMD Team Develops Design Optimization Framework for Ultra-High Efficiency Heat Exchangers for Extreme Temperature and Pressure Applications

August 6, 2025

In the June 1, 2025, issue of International Journal of Heat and Mass Transfer, researchers from the UMD Center for Environmental Energy Engineering (CEEE) present a comprehensive design optimization platform for a novel Triply Periodic Minimal Surface (TPMS)-based heat exchanger for high-temperature (900°C) and high-pressure (25 MPa) applications using air and supercritical CO2 as the working fluids. The next generation heat exchangers, which showed 10 times increase in volumetric power density compared to initial designs and are nearly three times smaller than conventional state-of-the-art printed circuit heat exchangers, are expected to push the boundary of efficient thermal management in high-temperature / high-pressure environments such as aviation and power generation.

The new framework utilizes a multi-scale modeling approach, allowing for full heat exchanger simulations in seconds, which is significantly faster than the several days typically required to conduct full computational fluid dynamics (CFD) simulations of the same heat exchanger architecture. “The ability to quickly and accurately predict the thermal performance of full heat exchangers is critical for conducting optimization, where tens of thousands – or even more – full heat exchanger designs are considered,” says co-author and CEEE Director Vikrant Aute, a research professor in the Department of Mechanical Engineering.

The other authors are former CEEE researcher Lalith Dharmalingam (M.S. ’21), now with Bloom Energy; graduate research assistant Brian O’Malley; and postdoctoral researcher James Tancabel.

Sample TPMS and their associated bi-continuous skeletal graphs: a) Gyroid (Schoen-G), b) Diamond (Schwartz-D), c) Primitive (Schwartz-P). From Han, L., & Che, S. (2018). An overview of materials with triply periodic minimal surfaces and related geometry: from biological structures to self‐assembled systems. Advanced Materials, 30(17), 1705708.

The framework optimizes heat exchangers that are based on special shapes called Triply Periodic Minimal Surfaces (TPMS) – the most well-known of these structures is the gyroid. At first glance, the undulating shapes look like three-dimensional Spirograph designs, but TPMS aren’t kiddie art projects: these complex geometries can pack a large amount of heat transfer area into a small envelope volume, resulting in highly compact heat exchangers.

“The future of thermal management is ultra-high-performance heat transfer equipment in incredibly small packages,” says Aute. “Smaller equipment means less material and more compact system packages, both contributing to reducing overall manufacturing costs,” he continues.

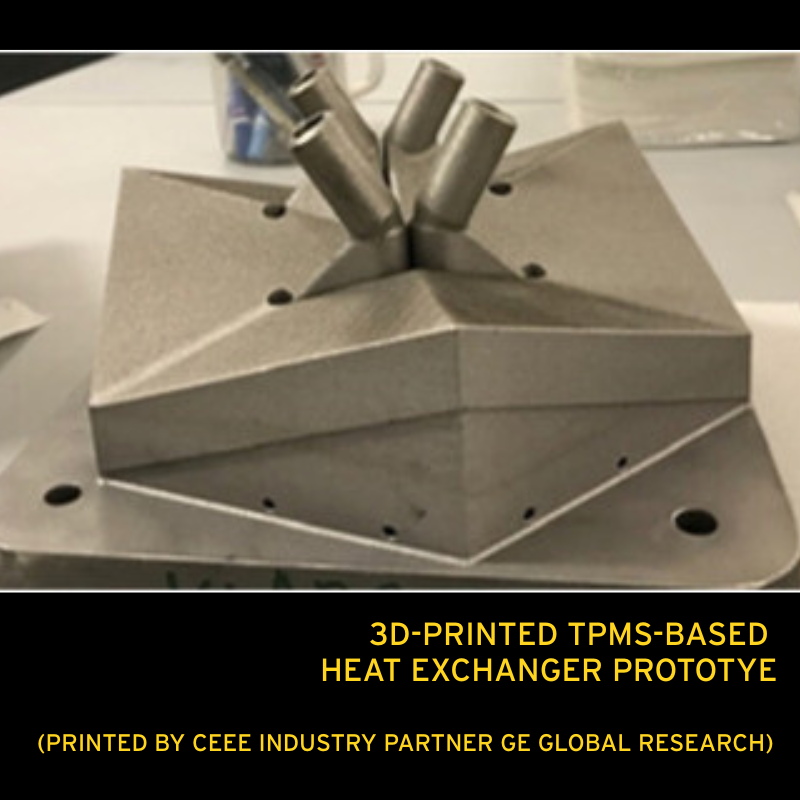

TPMS-based heat exchangers have recently gained popularity thanks to advances in additive manufacturing, or 3D printing, that have enabled researchers to produce reliable prototypes of these complex shapes for the first time. CEEE industry partner, General Electric Global Research, 3D printed multiple configurations of the novel heat exchanger design using a variety of alloys that can withstand high temperatures (up to 900℃) and high pressure (up to 25 MPa). These prototypes were used to experimentally validate the multi-scale model, within ±5% and ±10% for heat transfer and pressure drop, using water as the working fluid.

As a next step, CEEE is working to utilize TPMS-based heat exchangers for additional applications, such as liquid-to-refrigerant heat exchangers for heat pumps, water heaters and refrigeration systems.

Download the publication: “Design, optimization, and validation of a triply periodic minimal surface-based heat exchanger for extreme temperature applications.”